Composite cores for advanced conductors, also called High Temperature Low Sag or HTLS conductors, are used in overhead transmission and distribution lines to improve the line ampacity, reduce electrical losses and mitigate line sag.

Epsilon manufactures its composite cores in pultrusion, using Aerospace grade carbon fibers and a specific epoxy matrix to ensure the highest performance and durability.

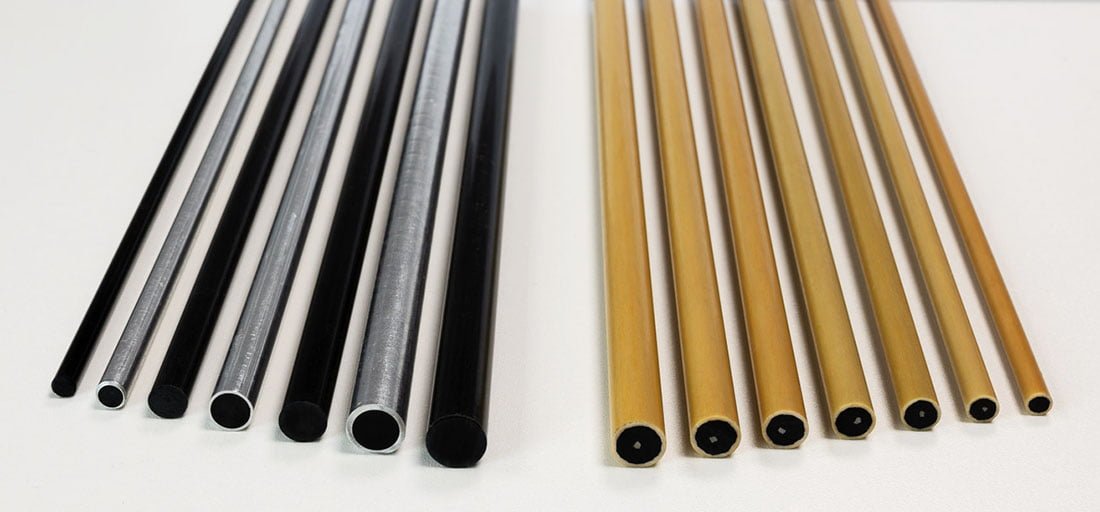

Our composite cores can either be:

- 100% carbon fiber cores, for various customer solutions (single-strand or multi-strand cores)

- Glass-carbon fiber hybrid cores, such as for HVCRC® conductors

Standard composite core dimensions available:

- Core diameter from 3mm to 30mm

- Spool length up to 10km

About pultrusion, our main manufacturing process

Composite cores main properties

You can find below the main properties of our most common standard composite cores:

Frequently Asked Questions

We answered below some of the most common questions we get about our composite cores: