Conductor classification & brand names: how to avoid a common confusion

Author: Joseph Sylvia – July 30th, 2024

In the field of electrical transmission, there has been growing confusion between brand names and technical categories, particularly concerning composite core conductors. It is imperative for utility professionals to avoid incorporating branding or marketing terms within their technical documents. While some manufacturers may blur the distinctions between brand names and technical categories, this practice can restrict utilities to a single supplier, thereby limiting healthy competition and flexibility.

CIGRE (International Council on Large Electric Systems)

CIGRE, the International Council on Large Electric Systems, is a global organization dedicated to the collaborative development and sharing of knowledge in the field of high-voltage electrical systems. Established in 1921, CIGRE aims to facilitate the exchange of technical information among engineers, technicians, researchers, and other professionals involved in the generation and transmission of high-voltage electricity. The organization is known for its technical brochures and standards, which help guide the industry in best practices and technological advancements.

CIGRE Technical Brochure 695: Categories of HTLS (High Temperature Low Sag) Conductors

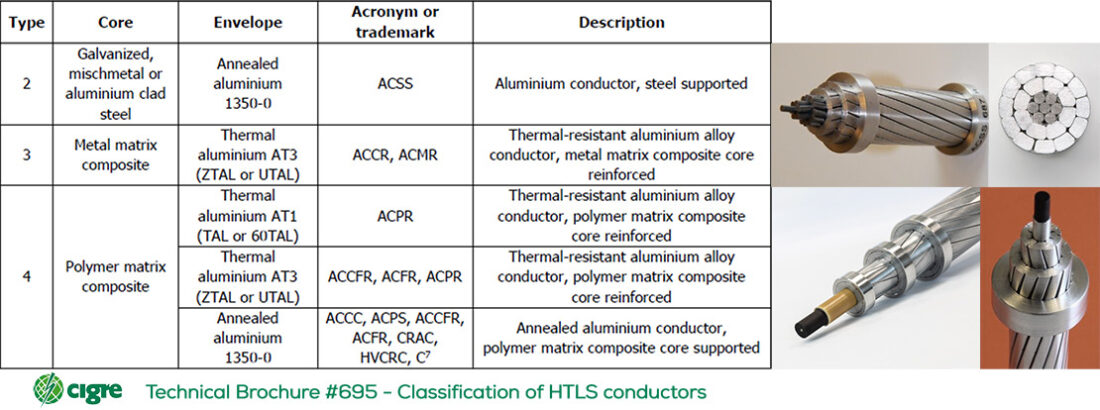

CIGRE Technical Brochure 695 categorizes HTLS conductors based on the materials used during manufacturing. These categories define the general technology and performance standards for various types of conductors and include:

| Type | Materials | Type of conductors (examples) |

| Type 0: conventional conductors | Limited to 95°C | ACSR, AAAC, AAC, ACAR |

| Type 1: Steel Core with Thermal Aluminum | Galvanized, mischmetal, aluminium clad or invar steel with thermal aluminum alloy wires | Gap, INVAR, TACSR… |

| Type 2: Steel Core with Annealed Aluminum | Galvanized, mischmetal or aluminium clad steel with annealed aluminum wires | ACSS |

| Type 3: Metal Matrix Composite core | Metal Matrix Composite (MMC) core with thermal aluminum wires | Various trade marks |

| Type 4: Polymer Matrix Composite core | Polymer Matrix Composite (PMC) core with either thermal or annealed aluminum wires | Various trade marks (see below for standard classification from ASTM) |

ASTM and industry specifications

The American Society for Testing and Materials (ASTM) has recognized that the electrical transmission industry lacks a comprehensive specification for conductors utilizing ASTM B987 carbon fiber composite (CFC) core material as the primary strength member. In response, ASTM plans to release revisions soon to include these technology categories, similar to the approach taken by CIGRE. This update will help standardize the industry and ensure consistent performance and quality across different manufacturers and types of conductors.

The ASTM designation for carbon fiber composite (CFC) core conductors is “ACCFCS”, for Aluminum Conductors, Carbon Fiber Composite Supported”.

As an active participant in both CIGRE and ASTM workgroups, Epsilon Cable is dedicated to advancing knowledge, standards, and best practices within electrical transmission and distribution globally.

Key differences and integration

- Type 4 HTLS conductors is a technology category that includes any conductor with a PMC (also called CFC) core and thermal or annealed aluminum. This category is defined by specific performance and material standards and is inclusive of multiple technologies and manufacturers.

- Glass-Carbon fiber hybrid composite core conductors is the most common technology within the type 4 HTLS conductor category and, with a composite core supplied by several manufacturers such as Epsilon Cable (under the ECRC® and HVCRC® trade marks) and CTC Global (under the ACCC® trade mark).

- 100% Carbon Fiber Core conductors designates another common technology of type 4 HTLS conductors where the composite core is encapsulated in an aluminum tubing. The composite core can also be supplied by several manufacturers, including Epsilon Cable. The most common trade marks for this type of conductors are ACPR and ACPS “Losag” from Nexans, and the ACCS from De Angeli.

You can read our previous “Expert Insights” article for a complete overview of existing Type 4 HTLS conductors.

Benefits of having multiple suppliers of composite core

For utility customers, having multiple suppliers for composite core conductors offers several advantages:

- Increased competition: multiple suppliers foster a competitive market, leading to better pricing, lead times, and improved product quality.

- Supply Chain resilience: diversification reduces the risk of supply chain disruptions, if one supplier faces production issues or delays, others can step in to meet demand.

- Innovation and variety: different manufacturers bring unique innovations and technologies to the market, providing utility customers with a broader range of options to suit specific needs and applications.

- Risk management: relying on a single supplier can be risky if that supplier encounters technical, financial, or operational difficulties. Multiple suppliers mitigate this risk.

- Customization and flexibility: with several suppliers, customers have the flexibility to select products that best fit their technical specifications and project requirements.

Conclusion

Having multiple composite core suppliers ensures a competitive, resilient, and innovative market, ultimately benefiting utility customers through better pricing, supply chain stability, and a wider selection of high-quality products.

The Type 4 category, as defined by CIGRE Technical Brochure 695, includes all HTLS conductors with a polymer matrix composite core (PMC).

Within this category, Epsilon Cable (a division of Epsilon Composite) is a distinguished supplier, leveraging over 35 years of experience in composite engineering and manufacturing. Epsilon produces both 100% carbon fiber and glass-carbon fiber hybrid core for Type 4 HTLS conductors and is the only supplier worldwide qualified for both technologies, with an extensive track record of each.

About the author, Joseph Sylvia

Joseph is Epsilon Cable’s Director of Business Development in the US. He is passionate about delivering innovative solutions that improve the efficiency and sustainability of the power industry.