Composite cores for advanced conductors, also called High Temperature Low Sag or HTLS conductors, are used in overhead transmission and distribution lines to improve the line ampacity, reduce electrical losses and mitigate line sag.

Epsilon manufactures its composite cores in pultrusion, using Aerospace grade carbon fibers and a specific epoxy matrix to ensure the highest performance and durability.

Our composite cores can either be:

- 100% carbon fiber cores, for various customer solutions (single-strand or multi-strand cores)

- Glass-carbon fiber hybrid cores, such as for HVCRC® conductors

Standard composite core dimensions available:

- Core diameter from 3mm to 30mm

- Spool length up to 10km

About pultrusion, our main manufacturing process

Composite cores main properties

You can find below the main properties of our most common standard composite cores:

View properties for 100% carbon fiber cores

View properties for HVCRC® composite cores

View properties for HVCRC® ULS (ultra low-sag) composite cores

Frequently Asked Questions

We answered below some of the most common questions we get about our composite cores:

How can I predict the lifetime of my line if I install composite core conductors?

Our composite experts have developed a powerful simulation tool for the ageing of our composite core in real life conditions. Based on this unique model, we are able to assess the lifetime of the conductors based on the real use of the line and the end of life criterion set by the utility.

The presentation of this model won the Next Generation Network Award at CIGRE 2022 in Paris (read more).

Why is a galvanic corrosion protection required on the composite core?

Composites are corrosion proof, but since carbon fibers are electrically conductive, aluminum strands in contact with it would corrode in the presence of an electrolyte such as water. This is why a suitable galvanic corrosion barrier as per ASTM B987 requirements (such as the glass fiber layer on HVCRC®), or an aluminum tubing providing similar protection is absolutely required for a durable performance of the line.

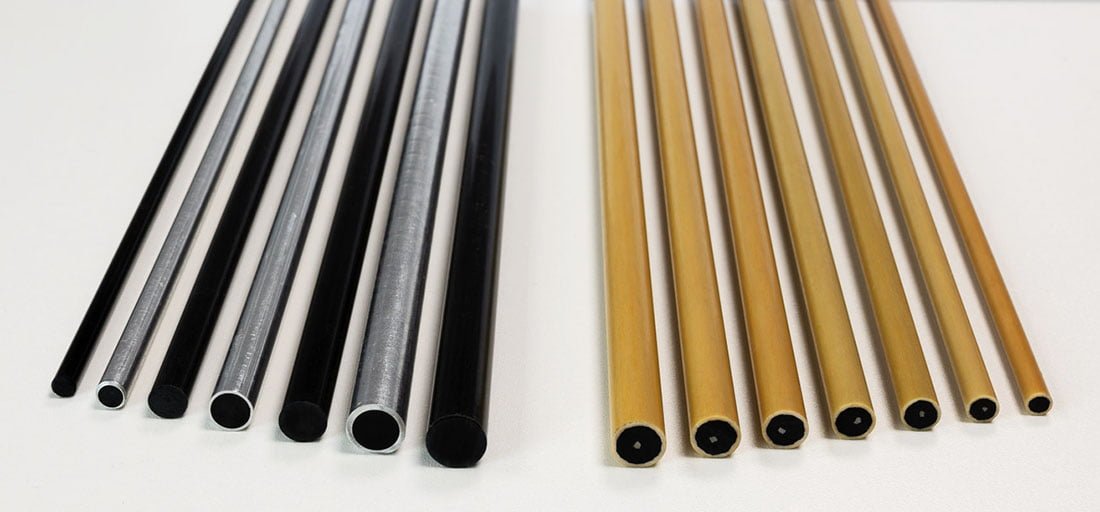

What is the difference between carbon-glass fiber hybrid cores and 100% carbon fiber cores?

HVCRC® cores have an embedded galvanic corrosion barrier (as per ASTM B987 standard) in the form of a glass fiber external layer, while 100% carbon fiber cores rely on an aluminum tubing for galvanic corrosion protection.

The glass fiber layer on HVCRC® cores is directly made in the pultrusion process during the core manufacturing, which makes it very economical and reliable.

Solutions with and aluminum-tubing require an additional manufacturing step with a specific process (such as extrusion or continuous welding). This is a technically proven solution, but this extra step makes aluminum-tubing solutions more complex from an engineering and industrial perspective, and therefore more costly.

However, using a 100% carbon fiber core with aluminum tubing does have benefits, such as a slightly higher tensile strength and E modulus. This can be especially useful in lines with ice load requirements, for example.

At Epsilon, we manufacture both types of cores depending on utilities specific requirements. We supply hybrid carbon-glass fiber profiles (such as HVCRC®) to our stranding partners, and we supply 100% carbon fiber cores to innovative stranders who designed their own HTLS technology (such as Nexans and De Angeli Prodotti).

How can I check the composite core?

Our CORECHECK® technology allows to check the structural integrity of our composite cores at any stage of their life: after the pultrusion process, after stranding, after transport, after installation, and at any time in the conductor lifetime.

What is HVCRC®?

HVCRC® is Epsilon’s original range of advanced conductors (High Capacity / High Temperature Low Sag conductors) made of a strong lightweight composite core and highly conductive trapezoidal aluminum wires.

As compared with traditional ACSR conductors, HVCRC® allows to double the ampacity of a transmission or distribution line, to decrease line losses by up to 30%, and provides many other benefits.

Who invented composite cores for high voltage overhead lines?

Brandt Goldsworthy and his team in the 1990’s. He had the idea to replace the traditional steel core in High Voltage conductors with a composite core, and laid out the foundation for the first generation of composite conductors.

In fact, M. Goldsworthy was nicknamed “the father of composites” as he also co-invented the pultrusion process and various other composite processes. Epsilon’s founder Stéphane LULL and his associate Laurent GUITTON (VP Business Development of Epsilon Cable) had the opportunity to work with M. Goldsworthy in California around the same period, before he passed away. We are proud to have carried on his work and his legacy to this date, as we refined the pultrusion process and developed the HVCRC® and other technologies with partners from all over the world.

Where are Epsilon composite cores produced?

All our composite cores are produced in our French factory, near the city of Bordeaux. The constant supervision of our skilled pultrusion experts allows us to ensure the highest process control, to avoid any potential defects and guarantee the product quality.

What is Pultrusion?

The term “pultrusion” is composed of “pull” and “extrusion”. Pultrusion is an automated and continuous process used to manufacture high performance composite profiles with a constant cross section, such as composite cores for HTLS conductors.

Carbon fiber pultrusion is the core business of Epsilon Composite, which is the pioneer and world leader of this industry since 1987.